08 Jun How Experts React to a Global Crises Part 1 | Recycling Services Case Study

How do you respond when a project isn’t going as planned? Large deviations lead to contract terminations and, in worst cases, litigation. But how do you respond when project deviations come from an unavoidable global crisis? In 2020, the COVID-19 pandemic created fallout across every industry around the world, but some organizations were more prepared than others.

In 2018, a large international organization based in Utah used the Best Value Approach (BVA) to hire an expert recycling services vendor. Within six months of signing the contract, revenue decreased drastically due to supply chain issues in China, and two years later the COVID-19 pandemic created massive deviations. In many cases, these crises could have ruined the project and resulted in failure, but since the vendor was an expert, they averted disaster.

When a global crisis occurs, even expert vendors can’t keep a project safe from all deviations. Nevertheless, experts are the best equipped to mitigate risk and reduce negative impacts.

In this article, we will explore a recycling services case study to show how a company ensured they were hiring an expert and how the expert mitigated risk.

Finding an Expert Vendor

In the Best Value Approach, experts are people who accurately plan for the future, simplify project information, and can tell the difference between what is possible and impossible. One of the key challenges to preparing for a crisis is ensuring that you have an expert readily available. Only experts will have the wherewithal to understand project conditions and mitigate risk.

In 2015, the State of Utah issued a mandate requiring all organizations to reduce their landfill waste by 50%. A large Utah-based organization did not have the knowledge or resources to implement this change. They decided to use the BVA to find an expert recycling services vendor.

The BVA is designed to prioritize expertise above all other factors (price, experience, relationships, etc.) The best way to find an expert is to create an RFP that requires vendors to submit verifiable performance metrics that justify their ability to meet project requirements, mitigate risk, and add value.

When the large organization issued their RFP, two vendors responded (Vendor A and B). Both vendors had relevant experience backed by metrics. The decision came down to price—Vendor B was offering over $350k more revenue than Vendor A. If a vendor is an expert, they should always be able to justify their price/revenue with a simple explanation. For that reason, the client invited both vendors to an additional interview to explain their pricing model.

After the interview, it was clear that Vendor B had more expertise. When asked about their price, Vendor A was unable to provide an explanation—they needed to begin the project to make an accurate estimate. Vendor B had a precise explanation for their revenue model. In addition, Vendor B explained that their revenue was higher because they were looking for innovative ways to deliver the project. Instead of only managing recyclable material, they also proposed adjustments to the facility that would allow them to manage all waste and increase revenue from recyclable material.

After the interview, it was clear that Vendor B had more expertise. When asked about their price, Vendor A was unable to provide an explanation—they needed to begin the project to make an accurate estimate. Vendor B had a precise explanation for their revenue model. In addition, Vendor B explained that their revenue was higher because they were looking for innovative ways to deliver the project. Instead of only managing recyclable material, they also proposed adjustments to the facility that would allow them to manage all waste and increase revenue from recyclable material.

Vendor B was then asked to create a detailed project plan which included a schedule, a risk mitigation plan, and a weekly risk report (WRR) to track project performance. When the vendor responded, it was clear they were an expert because:

- Their plan was simple and provided services beyond the RFP requirement (managing both recycling and waste).

- Their WRR allowed the client to track all key performance metrics to track costs, revenue, and any deviations.

- The vendor created an innovative pricing model that did not charge a management fee but would take 22% of all recycling revenue and give the client the remaining 78%.

- The plan would accommodate for all implementation costs (including facility adjustments).

Responding to the Crisis

By the end of Year 1, the project faced its first crisis. The supply chain for recycling material was impacted by new sanctions on China. Project revenue was $254k lower than estimated and costs were $153k higher. By Year 3, the COVID-19 pandemic affected building usage and decreased waste volume— leading to even lower revenue.

Despite the significant deviation, the client continued to renew the vendor’s contract because of how well they responded to both crises. The vendor did two things that saved the project:

- They created transparency.

- They found new ways to lower costs.

1 – Creating Transparency

The key to project transparency is simplifying information so every stakeholder can understand project conditions. Before the project started, the vendor created an effective weekly risk report that would highlight project conditions (schedule, revenue, cost, and deviations). The vendor included a section that allowed the client to see how their revenue deviated from the initial projections and from their competitor’s projections. The client was able to track progress without having to trust the vendor. A WRR is crucial to help clients analyze the situation and make important decisions (Kashiwagi, 2019).

The WRR didn’t change the project or avert the crisis, but it put the client at ease. Even though projections were off, the client was able to see how the vendor was responding to risk and adding value. In this project, the vendor was adding value by either 1) increasing revenue from recyclable materials or 2) lowering the costs of waste management.

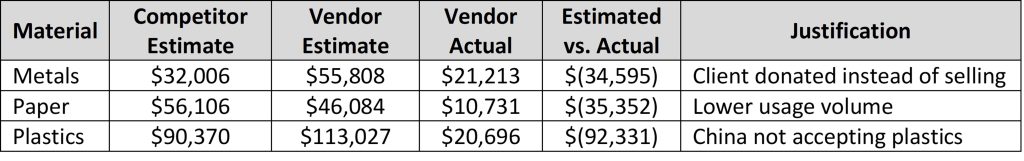

Transparency was crucial in managing revenue deviations. The vendor’s Year 1 WRR showed that there was a deviation of $250k from the projected revenue. Alone, this number only tells us that the revenue was lower than expected. To add more clarity, the vendor created a table to show deviations for each recyclable material (Table 1). This allowed the client to see all revenue deviations and understand why they were happening. Out of 13 different materials, the client and building users were responsible for 6 of the revenue deviations (46%). This information helped the vendor identify key areas to lower costs and it showed the client that cost deviations weren’t coming from the vendor’s mismanagement.

Table 1: WRR Snapshot | Materials with the Highest Deviation

2 – Lowering Cost

2 – Lowering Cost

There are only two ways to lower cost on a project, reduce quality or improve efficiency. Improving efficiency requires expertise because efficiency comes from planning, simplifying, and understanding project conditions.

In the previous example, we discussed how the vendor responded to revenue deviations. As soon as cost deviations occurred in Year 1, the vendor looked for different ways to cut costs and save the client nearly $200k. These cost-cutting measures included changes to the facilities, forming more efficient partnerships, and eliminated unnecessary administrative costs.

For example, through the WRR, the vendor discovered that 39% of cost deviation in Year 1 came from building users failing to sort material correctly. To mitigate this deviation, the vendor installed new garbage bins, simplified the sorting process, and found a method to recycle unusual materials. These measures saved nearly $20k. In addition, the vendor identified which materials weren’t selling as well compared to previous years, so they found new markets and services providers, which saved an additional $55k.

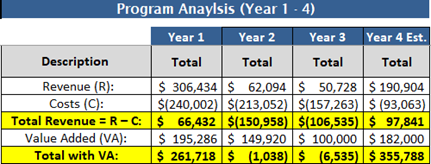

During Years 2 and s3, revenue dipped into the negatives (primarily because of market shifts and the COVID-19 pandemic). Despite the crisis, the vendor continued to add value and cut costs (Table 2). At the time of publishing this article, the vendor is halfway through Year 4 and anticipating a revenue of over $350k (a 34% increase).

Table 2: Recycling Program Revenue by Year

How to Prepare for a Crisis

Global crises are inevitable, but if we prepare, we can mitigate negative impacts. The two most important steps to preparing for a crisis are:

- Clients should focus on hiring expert vendors who use metrics and information to justify their ability to meet project requirements.

- Vendors should focus on creating transparency before and during a project.

When comparing vendors, clients should place a higher importance on expertise than on any other factor. Clients can measure expertise by using past performance metrics and asking vendors to justify their plans and prices. If organizations can focus on utilizing expertise, they will always be better equipped to mitigate risk in any situation (crisis or no crisis).

By creating transparency, vendors protect themselves from unjust accusations and makes it easier to find and mitigate sources of risk. Many times, crises cannot be averted, but vendors can use their project information to reassure clients and justify their own value.

For more information on how to find expert vendors and how to create project transparency, see these resources:

- Free membership for latest tips and news: https://pbsrg.com/membership/

- For latest books, events, and licensed partners: https://pbsrg.com/resources/

- Latest BVA journal publications: cibw117.org/

- Annual Best Value Conference in January: https://bestvalueconference.ksm-inc.com/

- Latest presentations and videos: https://www.youtube.com/channel/UCxBi26nXLDTqG4ZRV6p0iiQ

References

Kashiwagi, D. (2021). Best Value Approach for Vendors, Performance Based Studies Research Group, Mesa, AZ. Publisher: KSM Inc., 2022

PBSRG (2022). Performance Based Studies Research Group. Retrieved February 2022 from PBSRG Website: https://pbsrg.com/best-value-approach/