18 Aug Procurement Tip: The Pitfall of Minimum Standards

Picture Credit: Photo by fauxels from Pexels

Today’s procurement tip is on minimum standards. As the buyer defines their requirements, they are apt to set minimum standards. Minimum standards have become common practice in the industry as a means to protect the buyer and guarantee a minimum acceptable level of quality. However, buyers are often unaware that minimum standards produce the complete opposite outcomes as expected.

The creation and use of minimum standards:

- Chases away high performing vendors, while allowing unqualified vendors to compete in projects.

- Guarantees the maximum level of performance they will receive and motivates all vendors to decrease their quality and performance.

- Forces the buyer to be the expert and take all responsibility for the project [including costs].

- Relies on standards which have no correlation to performance, quality, or safety.

All Vendors are Not Created Equally

When buyers set a minimum standard of performance, there will always be vendors that perform at a higher and lower level than that minimum. Inexperienced vendors who perform lower than the minimum will not know how to do the buyer’s project. However, by giving a minimum standard, the buyer has now given a descriptive list of instructions telling the inexperienced vendors exactly what to do. In other words, the buyer has now given unqualified vendors the chance to compete on their project, and act as if they have the necessary experience.

In contrast, a vendor who performs at a higher level than the minimum is not given any additional credit. At this point, many high performers will choose to simply walk away since the minimum requirement is inferior to what they provide—or the client’s minimum will not solve the intended problem and will make the vendor look bad in the end. High performers do not like to compete for jobs where their expertise is not utilized and appreciated.

The remaining vendors that reluctantly choose to compete are now forced to examine their product/service and look for ways to decrease their costs by reducing their quality and/or performance. This type of cost cutting increases risk to both the buyer and vendor as the vendor is attempting to deliver a product/service which they normally do not provide and because of that, do not know the level of performance it will produce.

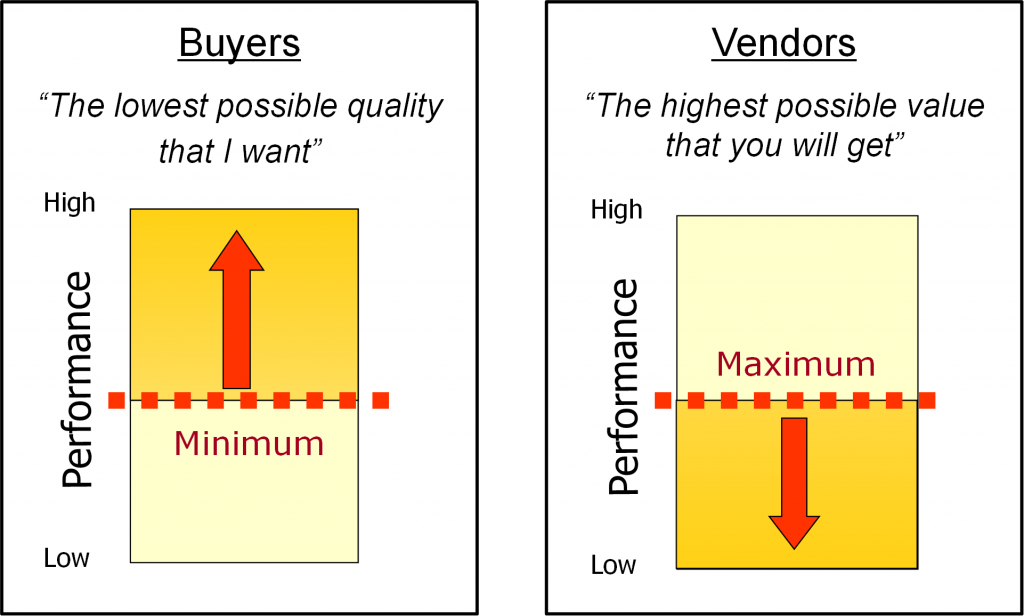

The Buyer’s Minimum is the Vendor’s Maximum

In the buyer’s mind, the minimum standard is to protect them from the risk of low performers. In the vendor’s mind, the client’s minimum now turns into the vendor’s maximum—the highest possible value the client will get. When clients decide that the main factor for winning a bid is the lowest cost is, the vendors sole objective becomes lowering their cost. Vendors intend to do the bare minimum to meet the client’s requirement in order to keep their costs low. The vendors only concern is to do exactly what was specified and possibility a little less, but definitely nothing more. Low performing vendors do this because they do not care about the project results—they just want to get the job and be paid. High performing vendors do this because it is the only way to compete with the prices of low performing vendors.

The Buyer Has to Be the Expert and Accept All Risk, While the Vendors Become Reactive

The Buyer Has to Be the Expert and Accept All Risk, While the Vendors Become Reactive

The biggest issue with the buyer setting the minimum standard is that it places the buyer in the role of the expert. The buyer is now responsible for ensuring that the minimum standard is 100% accurate and complete in solving their problem and delivering high performance. Since the buyer is the one who created the requirement, if any risk or problems occur, it will come at the financial cost to the buyer. Additionally, since the buyer is now acting as the expert, it is reducing the value of the vendor’s expertise and motivating them to be reactive. Instead of the vendor proactively solving the client’s problem, the vendor is now reactively waiting to do only what the client mandates. This becomes an issue as managing reactive vendors requires more time and resources.

Minimum Standards Force Vendors to Increase Costs and Decrease Quality

When creating and relying on standards, most buyers do not take the time to ask themselves how they know their standards will result in high performance. Buyers would be shocked to discover that most professional standards have no proven correlation to performance, safety, or quality. The majority of standards, whether created by professional organizations (such as ASTM, ISO and ANSI or by the buyer’s internal experts) are created through guess work and never tested or measured in practice. Minimum standards focus on measuring a product/service within silos but does not look at its capability as a whole to solve a problem.

For example, imagine we have a buyer who has a problem that they need solved—e.g., they need a clean building. In the ideal situation, the client could their problem and expect the vendors to come up with a solution which would deliver a clean building at the lowest cost. The vendors would be responsible for knowing how many times they would need to clean the windows, empty the trash, etc. In contrast, a client using minimum standards wouldn’t give the vendors their problem but would give a solution in the form of minimum standards that each vendor must meet. The client would tell the vendors how many times they will have to clean the windows, empty the trash, etc.

By defining minimum standards the client has now forced all vendors to divert their attention from solving the client’s problem, to meeting the minimum standard. A high performing vendor may know that windows should be cleaned more than prescribed by the client and that emptying the trash is required less frequently than prescribed. However, due to the client’s use of minimum standards the high performing vendor will lower their quality—giving the client exactly what they specified. The end result would be a building which has dirty windows and is overpriced due to paying too much for trash disposal. If the client wanted a clean building, they would then have to ask for additional window cleanings resulting in higher costs.

The Solution to Avoiding the Pitfall of Minimum Standards

When we consult buyers using the Best Value Approach, we instruct them to avoid minimum standards as much as possible. In fact, buyers should avoid prescribing what is technically required as much as possible. Instead, buyers should identify the problem they need solved whether that be the construction of a building, automation of processes through ICT software or a building which needs to be cleaned. The buyer should then let the vendors be responsible for delivering a solution which can solve that problem. In this way, vendors are no longer reactively looking to meet an arbitrary standard which may or may solve the buyer’s problem but instead are responsible to solve the problem itself and, in the process, set their own standards.

To learn more about the Best Value Approach and how this can be done see the following relevant resources:

- Free membership for latest tips and news: https://pbsrg.com/membership/

- For latest books, events, and licensed partners: https://pbsrg.com/resources/

- Latest BVA journal publications: www.cibw117.org/

- Annual Best Value Conference in January: https://bestvalueconference.ksm-inc.com/

- Latest presentations and videos: https://www.youtube.com/channel/UCxBi26nXLDTqG4ZRV6p0iiQ